Perfect across many industrial applications.

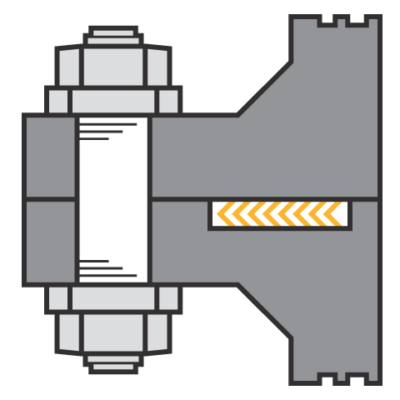

Spiral Wound Gaskets are a robust sealing product widely used across many industrial applications. Because of their robust nature, they can minimise downtime as they will need replacing less often. This makes them the perfect product for use across many industrial applications.

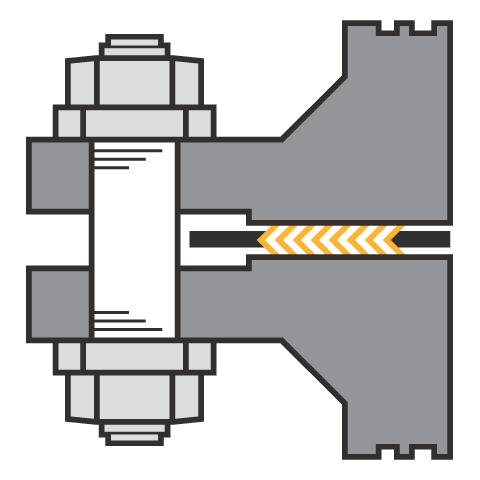

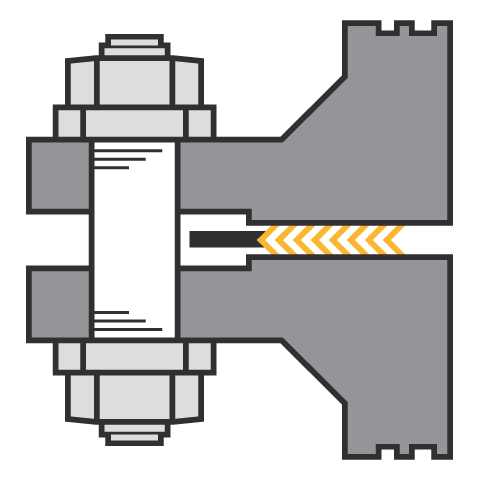

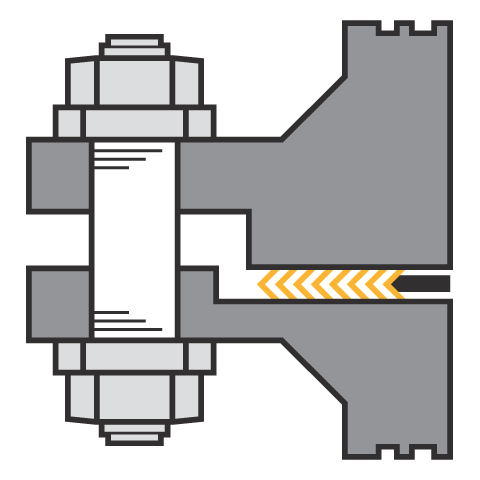

Spiral Wound Gaskets consist of a ‘V’ shaped metal strip spirally wound in combination with a soft filler material – normally Graphite, PTFE or Mica depending on the application and customer specification.

The gasket is easy to remove after service and does not cause any damage to the flange faces.

Contact Our Team